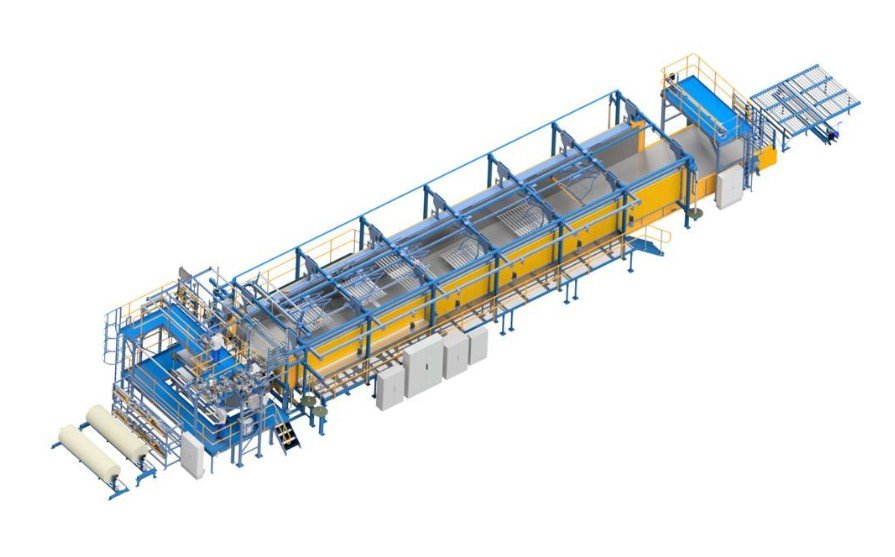

With the integration of our advanced AI-based Optiwise system into PURFORM slabstock plants, we are reshaping the future of polyurethane foam block production monitoring and control.

Optiwise harnesses cutting-edge artificial intelligence to deliver real-time monitoring and predictive maintenance across all key sections of the foaming process. By leveraging data-driven insights, our system identifies potential process faults and deviations before they escalate, ensuring maximum plant integrity and efficiency.

Key functionalities include:

- Early detection of process anomalies & potential faults

- Prediction of key process parameters & potential problems

- Comprehensive timeline records of operational events

- Anomaly identification across critical components

These capabilities allow us to provide unparalleled oversight and control, setting a new benchmark for operational excellence in the foam production industry.

Revolutionizing maintenance with AI

Traditional maintenance strategies often leave room for inefficiencies — whether through unexpected breakdowns or rigid preventive schedules. With Optiwise, we enable truly predictive maintenance, powered by real-time data collection and AI analysis. This approach allows us to anticipate equipment needs, optimize resource allocation, and minimize unplanned downtime. By transitioning from reactive to predictive methodologies, we ensure longer equipment lifespans and reduced operational costs.

The PURFORM + Optiwise advantage

The combination of PURFORM slabstock technology and Optiwise plant monitoring delivers transformative benefits, including:

- Reduced downtime and production loss

- Minimized waste of costly chemical raw materials

- Enhanced foam quality and consistency

- Streamlined maintenance scheduling and execution

- Improved working environments and safety standards

These innovations empower our clients to achieve superior productivity and profitability, all while maintaining the highest standards of environmental responsibility.