Turning Waste into Value

As industries worldwide prioritize sustainability, efficient methods for recycling and reusing materials have become essential. Rigid polyurethane (PU) foam, commonly used in the production of sandwich insulation panels, often generates significant production waste. Traditionally discarded, these PU scraps can now be repurposed into valuable resources thanks to advancements in recycling technologies.

Innovative recycling integration

Cannon’s specialized processes seamlessly reintroduce recycled PU into manufacturing lines. Production scraps are collected, ground into fine powder, and then used to produce new panels. Proprietary technologies — including reintegration modules, custom dosing units, and advanced mixing heads — enable the smooth and effective incorporation of recycled PU into existing workflows.

Two key recycling methods

Recycling rigid PU foam involves two primary methods: mechanical recycling and chemical recycling.

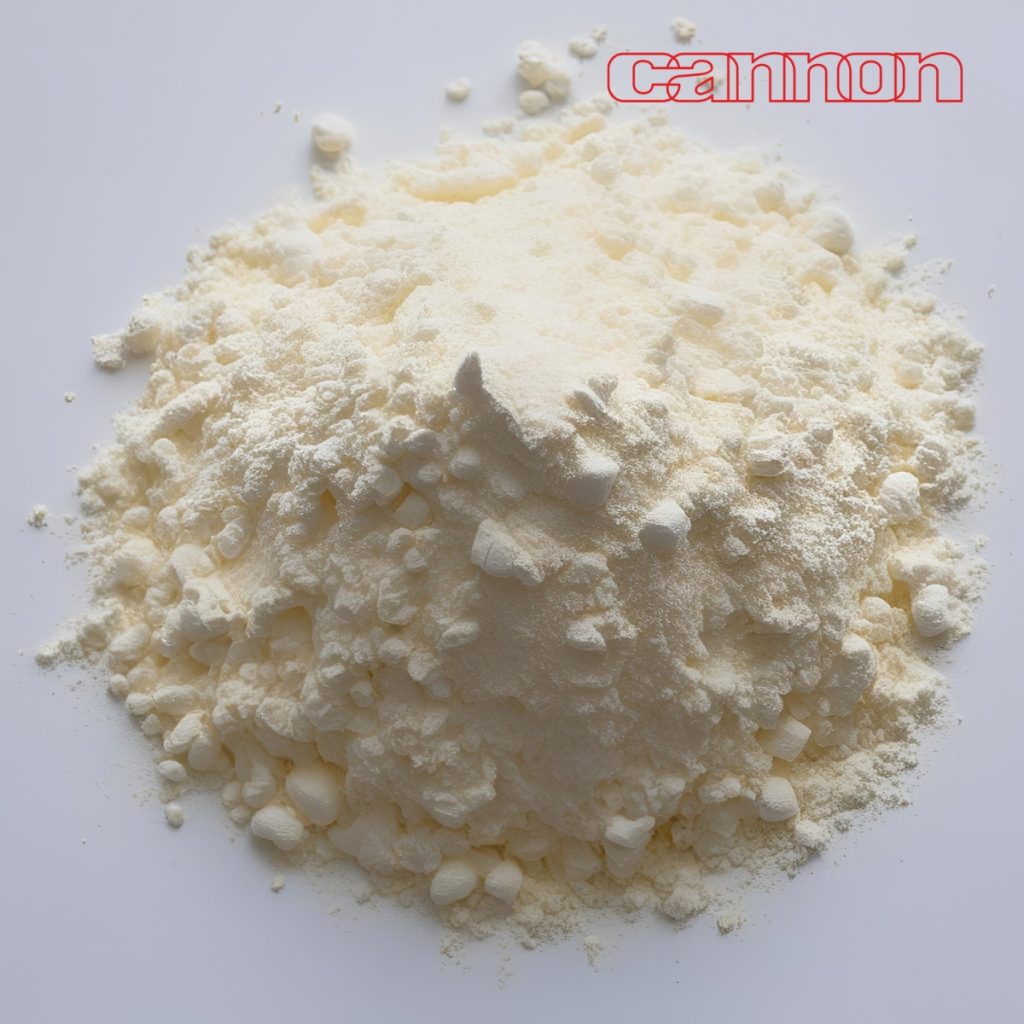

Mechanical recycling consists of grinding PU into powder and using it as a solid filler in new production. This method retains the material’s essential properties and provides a straightforward, cost-effective recycling solution.

Chemical recycling breaks PU down via chemolysis to recover polyol, a fundamental raw material in PU production. This advanced technique reduces dependence on virgin materials and supports closed-loop manufacturing — an important step in achieving a circular economy.

High-quality, sustainable results

Recycled PU delivers performance comparable to virgin polyurethane, making it a reliable substitute for a wide range of applications, including appliances. Whether used in rigid or flexible foam, Cannon recycling processes ensure the material maintains the high standards required for demanding manufacturing environments. This allows producers to achieve sustainability targets without sacrificing product quality.

Advancing sustainable manufacturing

Incorporating recycled PU into production offers manufacturers a clear path to reduce waste, decrease reliance on new raw materials, and significantly enhance their environmental performance. By adopting advanced recycling methods, companies can lead the charge toward sustainable manufacturing — contributing to a greener, more resource-efficient future.